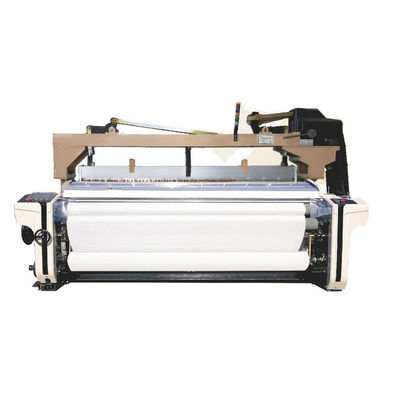

TONGDA are over 60 years old China Government group company and Top brand for textile machinery since 1952. And we are the Vice president Company of CTMA ( China Textile Machinery Association). Our main products are Weaving machines including the Air jet loom, water jet loom and rapier loom ,Yarn spinning machines. We exported to overseas market since 1988.

Laisser un message

Nous vous rappellerons bientôt!

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères!

Merci de consulter vos emails!

Merci de consulter vos emails!

SOUMETTRE

Plus d'informations facilitent une meilleure communication.

M.

- M.

- Mrs

D'accord

Soumis avec succès!

Nous vous rappellerons bientôt!

D'accord

Laisser un message

Nous vous rappellerons bientôt!

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères!

Merci de consulter vos emails!

Merci de consulter vos emails!

SOUMETTRE